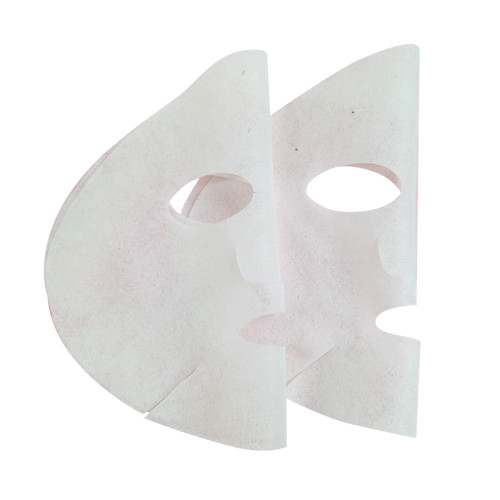

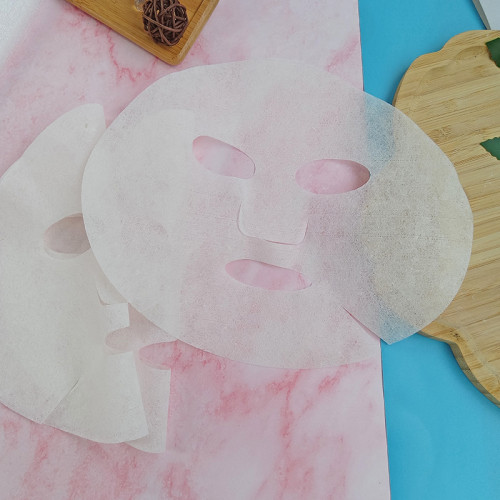

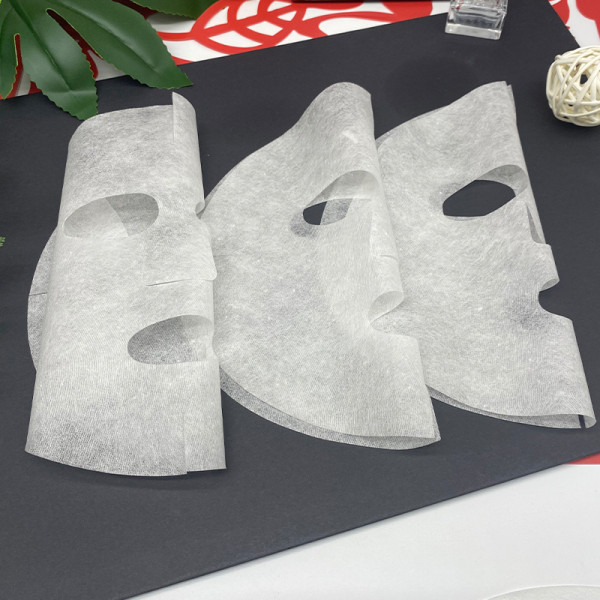

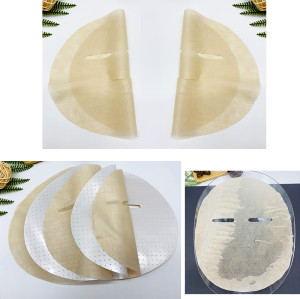

Organic face mask paper banana leaves fiber dry face mask spunlace mask sheet manufacturer

- Price

- US $0.07-0.08

- Model

- CFBL35

- MOQ

- 50000 piece

Item specifics

- Color

- White

- Ingredient

- Banana leaf Fiber

- Place of Origin

- Guangdong, China

- Brand Name

- Proyons

- Skin Type

- All skin types

- Feature

- bright, soft, elastic, skin repair

Review

Description

Product Description

As a professional spunlace nonwoven manufacturer, we have long been committed to the development of plant fiber spunlace nonwoven for sheet mask making substrates.

If you need to develop more plant fiber spunlace material, please feel free to contact us.

Banana leaves fiber is a all-natural green plant fiber made from banana trees and banana leaves planted in Guangdong, Guangxi,Yunnan and other provinces and regions in China, through the processes of degumming, spinning, drying, and cutting. The main body length of Banana leaves fiber is 38mm, and the fiber is white, milky white, brown or purple-black shiny. The texture is hard. The tensile strength of the fiber in the dry state can reach 4.5 moles, and the tensile strength in the wet state is greater. Banana leaves fiber contains 64-74% cellulose and 5%-8% lignin. Through the combined treatment of biological enzymes and chemical oxidation, the Banana leaves fiber is made by drying, scouring and defibrating the trunk and leaves of bananas. And environmental protection and other functions. The Banana leaves fiber can be spunlaced into fabric by pure spinning or blending with pure cotton fibers and other materials. The fabric has multiple additional functions, and the main development direction is to improve the gloss, softness, water absorption and transparency of the overall fabric. The fabric is mainly used in mask fabric and other spunlace non-woven products.

If you need to develop more plant fiber spunlace material, please feel free to contact us.

Banana leaves fiber is a all-natural green plant fiber made from banana trees and banana leaves planted in Guangdong, Guangxi,Yunnan and other provinces and regions in China, through the processes of degumming, spinning, drying, and cutting. The main body length of Banana leaves fiber is 38mm, and the fiber is white, milky white, brown or purple-black shiny. The texture is hard. The tensile strength of the fiber in the dry state can reach 4.5 moles, and the tensile strength in the wet state is greater. Banana leaves fiber contains 64-74% cellulose and 5%-8% lignin. Through the combined treatment of biological enzymes and chemical oxidation, the Banana leaves fiber is made by drying, scouring and defibrating the trunk and leaves of bananas. And environmental protection and other functions. The Banana leaves fiber can be spunlaced into fabric by pure spinning or blending with pure cotton fibers and other materials. The fabric has multiple additional functions, and the main development direction is to improve the gloss, softness, water absorption and transparency of the overall fabric. The fabric is mainly used in mask fabric and other spunlace non-woven products.

Parameter

Model NO.: | CFBL35 |

Product color: | White |

Process description: | Full cross spunlace |

Fabric Texture: | Plain |

Weight: | 35gsm |

Weight Range: | 25~150gsm |

Material: | Banana leaves fiber |

Linging cloth: | Single sheet (recommended to use interlining) |

Standard face size: | 220*200mm |

Customize face size: | YES |

Variety of materials be blended: | YES |

Finish: | Printing/Compression/Lyophilized powder finishing |

Feature: | Banana leaves fiber has multiple additional functions, and the main development direction is to improve the gloss, softness, water absorption and transparency of the overall fabric. The fabric is mainly used in maskfabric and other spunlacenonwoven products . |

|

Heavy Metal Detection Data:

Extractable heavy metal test method: refer to Testing Methods STANDARD 100 By OEKO-TEX (2017),detection and analysis by inductively coupled plasma emission spectrometer. |

||||

|

Testing Parameter

|

Units

|

Method detection limit (direct contact with skin) | Limit |

Result

|

|

(Pb)

|

mg/kg

|

0.1 | 0.2 |

ND

|

(Cd) | mg/kg | 0.01 | 0.1 | ND |

(Cr) | mg/kg | 0.1 | 1 | ND |

(Hg) | mg/kg | 0.01 | 0.02 | ND |

(Sb) | mg/kg | 3 | 30 | ND |

(As) | mg/kg | 0.2 | 0.2 | ND |

(Cu) | mg/kg | 2.5 | 50 | ND |

(Co) | mg/kg | 1 | 1 | ND |

|

(Ni)

|

mg/kg

|

1 | 1 |

ND

|

|

Result

|

Pass

|

|||

|

Testing Parameter

|

Method

|

Units

|

Test Result

|

|

Composition |

GB/T2910

|

%

|

Banana leaves fiber |

|

Weight

|

ISO 9073-1

|

g/m2

|

35.2

|

Thickness | PRIUS Standard | mm | 0.18 |

Speed of absorbability | FZ/T6402 | S/10cm | 28.6 |

White degree | GB/T 8424.2 | % | |

|

Tensile strength CD dry

|

ISO 9073-3

|

N

|

27 |

Tensile strength MD dry | ISO 9073-3 | N | 23.2 |

Breaking elongation CD dry | ISO 9073-3 | % | 129 |

Breaking elongation MD dry | ISO 9073-3 | % | 119.6 |

Capacity of liquid-absorbability | FZ/T 64012 | % | 1012 |

The microfiber has excellent adsorption properties can absorb 800 times its own weight so as to achieve the exfoliating effect.

Cotton pulp fiber is a new material developed by our company in 2021. It uses cotton as the main raw material.

This product is made of 30% cupro fiber combined with Lyocell fiber through a full-cross high-pressure spunlace process.

Anti-aging & firming biodegradable face mask skin care facial mask to solve skin problems.