Plant fiber facial mask camellia fiber organic material sheet mask fabric facial sheet mask fabric

- Price

- US $0.04-0.06

- Model

- CYN35HTL

- MOQ

- 50000 piece

Item specifics

- Color

- Light pink

- Ingredient

- 100% camellia fiber

- Place of Origin

- Guangdong, China

- Brand Name

- Proyons

- Skin Type

- All skin types

- Feature

- skin firmer, reduce wrinkles

Review

Description

Product Description

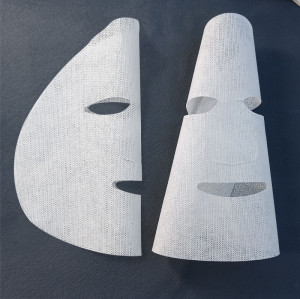

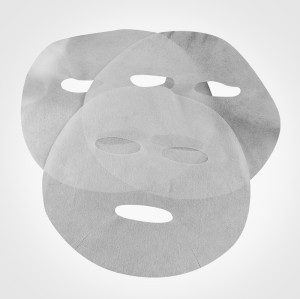

Plant fiber facial mask camellia fiber organic material sheet mask fabric facial sheet mask fabric

As a professional spunlace nonwoven manufacturer, we have developed a variety of different materials for face mask paper all year round. Plant fiber mask sheet is one of the mask fabric substrates that we highly recommend. If you are interested in this type of products, please feel free to contact us.

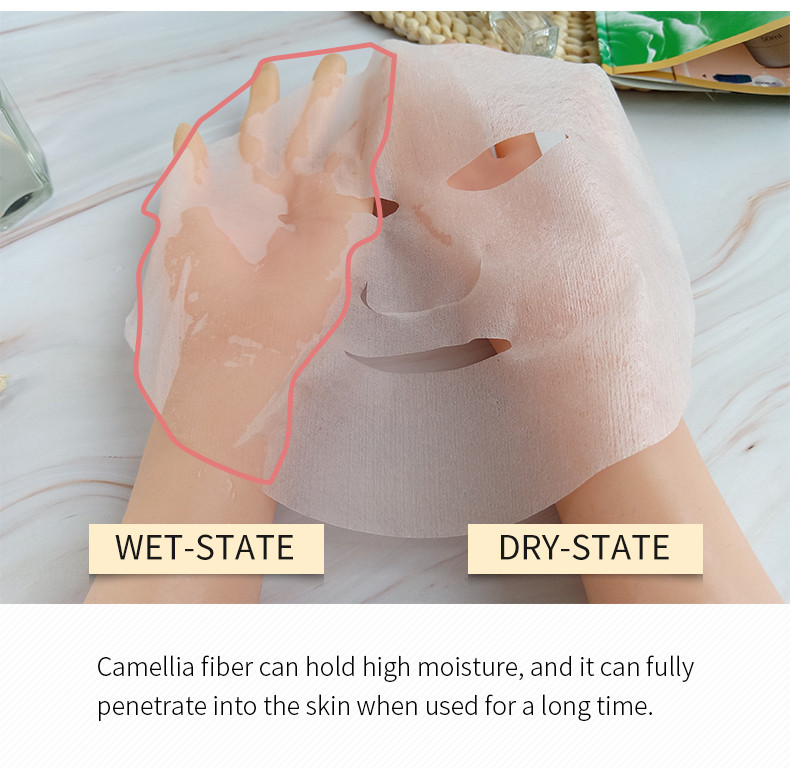

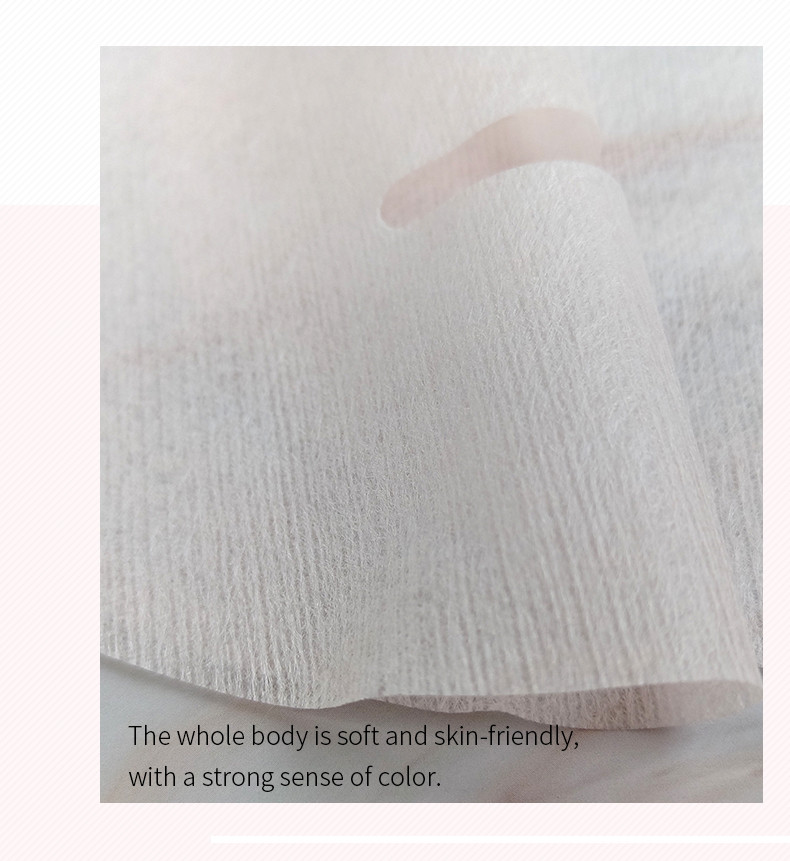

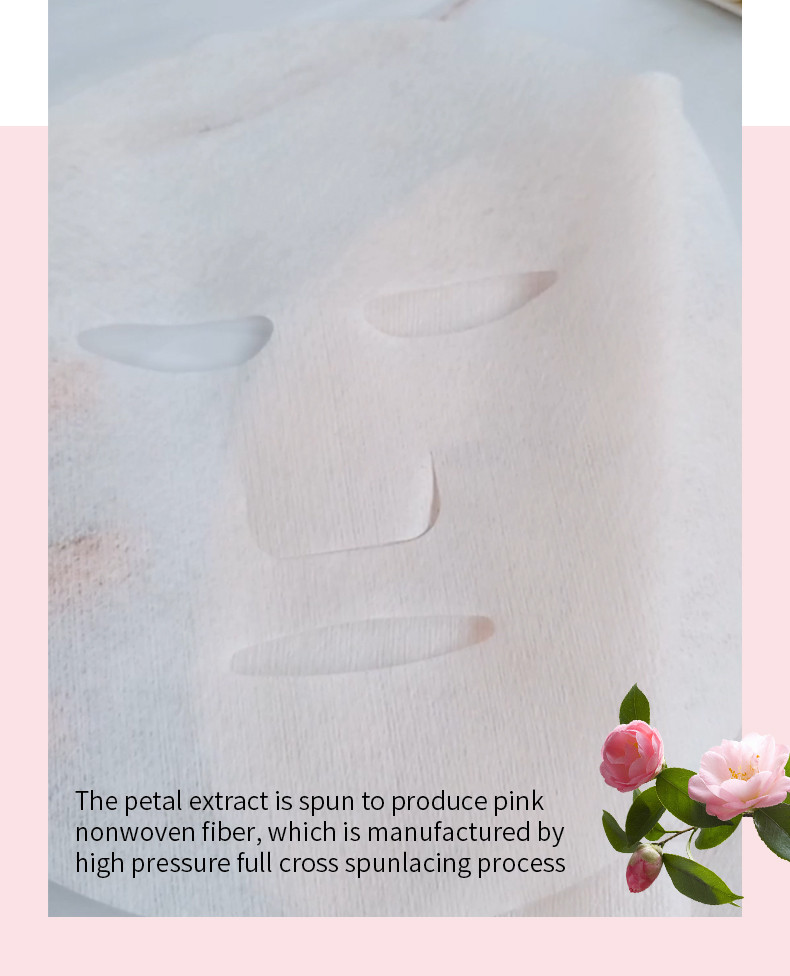

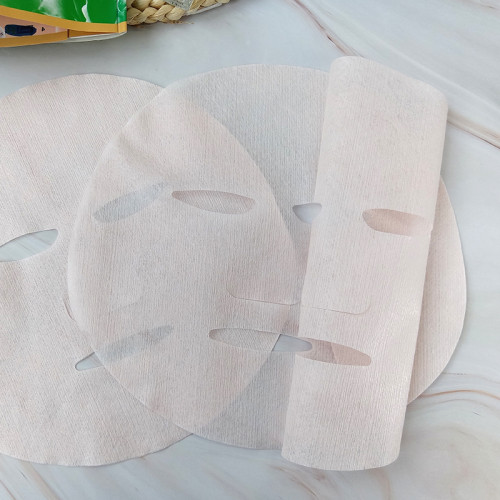

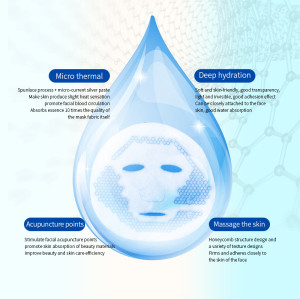

Proyons CYN35PYR camellia mask fabric is made of camellia fiber through full cross-laying and high-pressure spunlace. Camellia is rich in polyphenols, which can accelerate the metabolism of skin toxins, improve the elasticity and toughness of the skin, assist in making the skin firmer, reduce wrinkles, and keep the skin healthy and young. Camellia fiber can efficiently lock in moisture, relying on its high water absorption rate, long-term use can allow the material to fully penetrate the skin, nourish deeply, make the absorption of the material more efficient, and make the beauty material penetrate into the skin for a longer period of time, especially suitable for use Manufactures mask products for whitening types. Camellia fiber specification is 38mm spunlace fiber. Based on wood pulp foil, camellia flower extract is added to make camellia fiber, which is entangled into a multi-dimensional mesh-like fabric surface through high-pressure water entanglement. The multi-dimensional mesh structure adopts the vertical and horizontal cross arrangement. By adjusting the cutting direction of the film fabric, it can provide different application feeling and use effect. Provide multi-directional film fabric application effect and use experience for the face vertically and horizontally. The longitudinal and lateral tension ratio of the fabric surface is 1:0.8, which makes the horizontal multi-dimensional mesh have better elasticity when used, which is more conducive to the adjustment of the mask fabric according to different face shapes, and can lock more materials at the same time , to meet the longer service life. The slightly stronger longitudinal tension can more effectively improve the support and fit of the face up and down.

Parameter

Model NO.: | CYN35HTL |

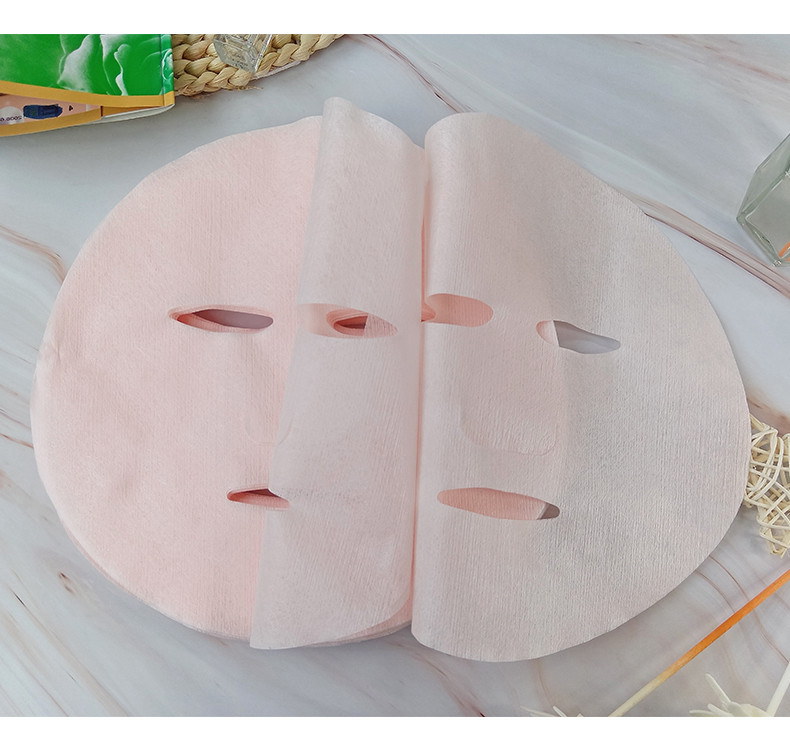

Product color: | Light pink |

Process description: | Full cross spunlace |

Fabric Texture: | Multi-dimensional mesh |

Weight: | 35gsm |

Weight Range: | 25-60gsm |

Material: | Camellia fiber |

Linging cloth: | Single Sheet |

Standard face size: | 210*210mm |

Customize face size: | YES |

Variety of materials be blended: | YES |

Finish: | Printing/freeze drying/compressed/compsite |

Feature: | It is rich in camellia extract, which can assist in improving the function and efficacy of beauty materials. The high-pressure hydroentangled multi-dimensional square hole structure is soft to the touch, and the horizontal multi-dimensional mesh is more elastic than the vertical one, which can improve multi-directional facial application, improve material introduction efficiency, use time and facial coverage. |

|

Heavy Metal Detection Data:

Extractable heavy metal test method: refer to Testing Methods STANDARD 100 By OEKO-TEX (2017),detection and analysis by inductively coupled plasma emission spectrometer. |

||||

|

Testing Parameter

|

Units

|

Method detection limit (direct contact with skin) | Limit |

Result

|

|

(Pb)

|

mg/kg

|

0.1 | 0.2 |

ND

|

(Cd) | mg/kg | 0.01 | 0.1 | ND |

(Cr) | mg/kg | 0.1 | 1 | ND |

(Hg) | mg/kg | 0.01 | 0.02 | ND |

(Sb) | mg/kg | 3 | 30 | ND |

(As) | mg/kg | 0.2 | 0.2 | ND |

(Cu) | mg/kg | 2.5 | 50 | ND |

(Co) | mg/kg | 1 | 1 | ND |

|

(Ni)

|

mg/kg

|

1 | 1 |

ND

|

|

Result

|

Pass

|

|||

|

Testing Parameter

|

Method

|

Units

|

Test Result

|

|

Composition |

GB/T2910

|

%

|

Camellia fiber |

|

Weight

|

ISO 9073-1

|

g/m2

|

35.5

|

Thickness | PRIUS Standard | mm | 0.17 |

Speed of absorbability | FZ/T6402 | S/10cm | 24.2 |

White degree | GB/T 8424.2 | % | |

|

Tensile strength CD dry

|

ISO 9073-3

|

N

|

22.9

|

Tensile strength MD dry | ISO 9073-3 | N | 24.8 |

Breaking elongation CD dry | ISO 9073-3 | % | 134.8 |

Breaking elongation MD dry | ISO 9073-3 | % | 125.5 |

Capacity of liquid-absorbability | FZ/T 64012 | % | 981 |