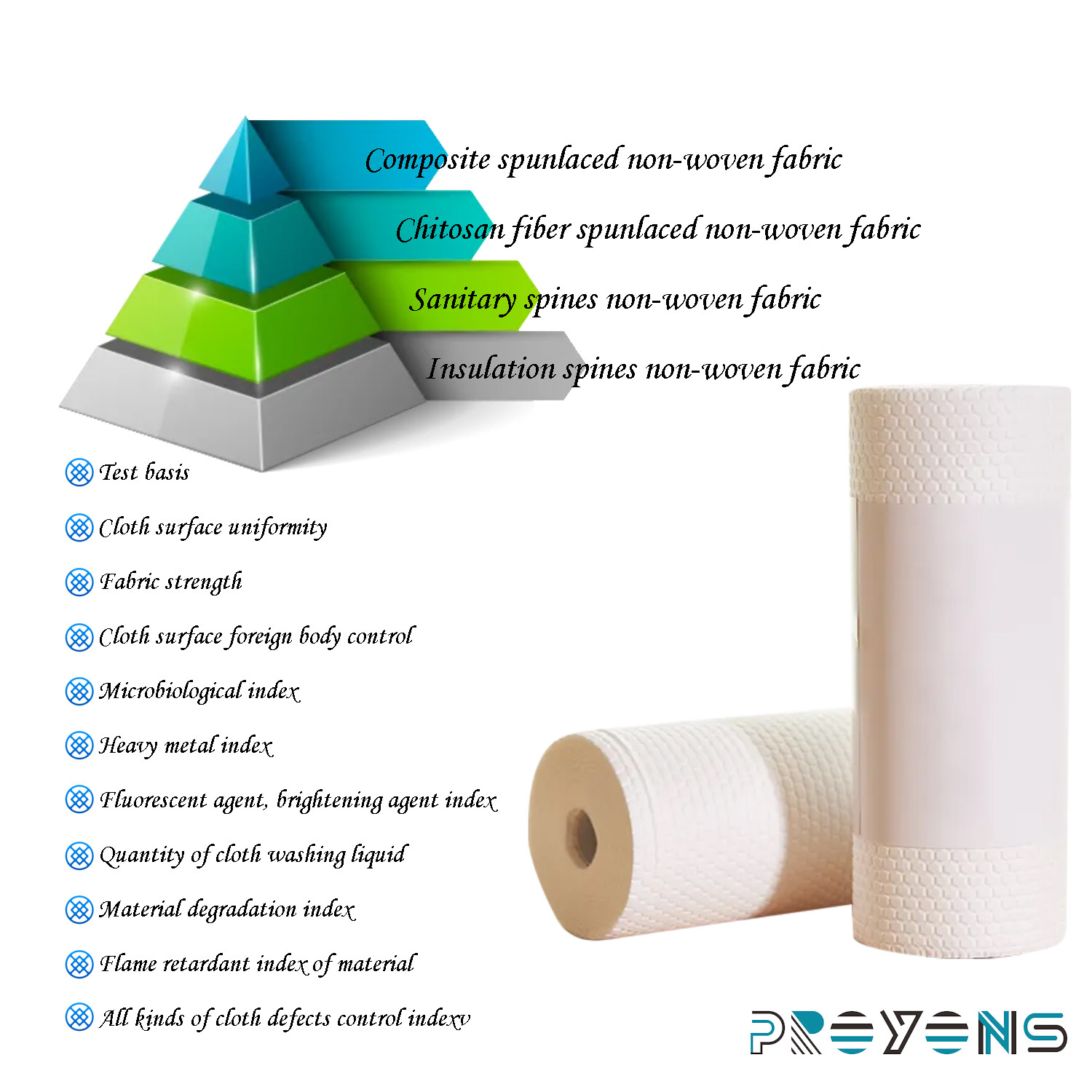

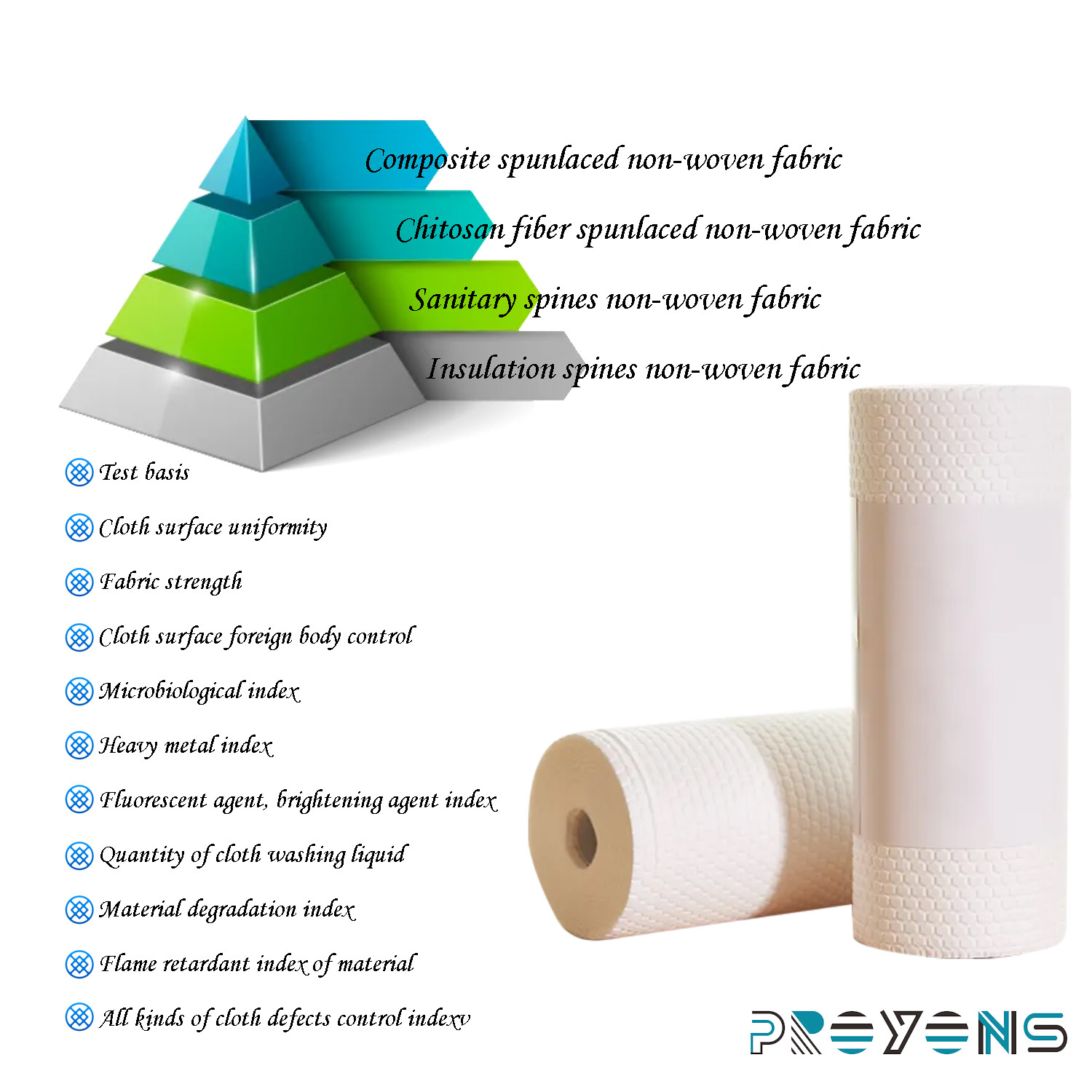

Four types of spunlace nonwovens - testing items and standard reference

- Share

- publisher

- Amanda

- Issue Time

- Feb 27,2023

Summary

In my country, spunlace non-woven fabrics are mainly used in medical and sanitary products, beauty industry, light industrial production, electronics industry, environmental protection and other fields, which play a positive role in promoting the development of traditional chemical fibers and differential fibers in my country.

Four types of spunlace nonwovens - testing items and standard

reference

In my country, spunlace non-woven fabrics are mainly used in

medical and sanitary products, beauty industry, light industrial production,

electronics industry, environmental protection and other fields, which play a

positive role in promoting the development of traditional chemical fibers and

differential fibers in my country.

Spunlace non-woven fabric is an important raw

material for mask products, medical masks, medical protective clothing,

medical dressing gauze, surgical gowns, and artificial leather base cloth. How

to grasp the quality of spunlace nonwovens through testing is a concern of

relevant manufacturers.

1. Testing of composite spunlace nonwovens

Composite spunlace nonwovens can be tested according to the

regulations in GB/T 26379-2011 "Textiles - Wood pulp composite spunlace

nonwovens". GB/T 26379-2011 divides composite spunlace nonwovens into

ordinary and functional composite spunlace nonwovens.

Among them, functional composite spunlace non-woven fabrics are

mainly used for special purposes such as water repellency and flame retardancy.

The external quality inspection items of the two composite spunlace nonwovens

are the same, but the internal quality inspection items are slightly different.

The specific requirements are as follows:

(1) Intrinsic quality inspection items of ordinary composite

spunlace non-woven fabrics: mass deviation rate per unit area, mass unevenness

per unit area, transverse breaking strength, absorption capacity, color

fastness to rubbing, and width deviation;

(2) Internal quality inspection items of functional composite

spunlace non-woven fabrics: mass deviation rate per unit area, mass unevenness

per unit area, transverse breaking strength, color fastness to rubbing, width

deviation, water seepage resistance, water staining performance, anti-alcohol

performance, flame retardant performance;

(3) External quality inspection items of composite spunlace

non-woven fabrics: linear defects, poor trimming and edge cutting, bad curling,

printing and dyeing defects, splicing times, stains, stains, impurities,

damaged defects, delamination, insects trace etc.

2. Chitosan fiber spunlace non-woven fabric detection

Chitosan fiber spunlace nonwovens can be tested according to the

regulations in FZ/T 64077.2-2019 "Chitosan fiber nonwovens Part 2:

Spunlace nonwovens". The testing items of chitosan fiber spunlace

nonwovens are basically similar to those of hygienic spunlace nonwovens, and

are also divided into three items: internal quality, external quality, and

microorganisms. Specific requirements are as follows:

(1) Internal quality inspection items: mass deviation rate per

unit area, width deviation, longitudinal and transverse fracture strength,

deviation rate of chitosan fiber content, pH value, formaldehyde content,

migratable fluorescent substances, liquid absorption, antibacterial rate, heavy

metal content (lead, mercury, arsenic);

(2) External quality inspection items: cloth surface, joint,

slitting end surface;

(3) Microbial index testing items: total bacterial colony,

coliform, total fungal colony, pathogenic pyogenic bacteria, etc.

3. Inspection of hygienic spunlace non-woven fabrics (including facial

mask fabric)

Hygienic spunlace nonwovens

can be tested according to the regulations in FZ/T 64012-2013 "Sanitary

spunlace nonwovens". FZ/T 64012-2013 divides the inspection items of

hygienic spunlaced nonwovens into three categories: internal quality

inspection, external quality inspection, and microbial index inspection. The

specific reference inspection items are as follows:

(1) Internal quality inspection items: mass deviation rate per

unit area, mass variation coefficient per unit area, thickness deviation,

breaking strength, width deviation, liquid absorption, pH value;

(2) External quality inspection items: fabric surface quality

defects, color difference, blemishes, etc.;

(3) Microbial index testing items: total bacterial colony,

coliform bacteria, Staphylococcus aureus, pathogenic pyogenic bacteria, etc.

4. Testing of insulating spunlace nonwovens

Insulation spunlace nonwovens can be tested according to the

regulations in FZ/T 64065-2017 "Aramid spunlace nonwovens for

insulation". Insulating spunlaced nonwovens only need to test two items of

internal quality and external quality. Specific requirements are as follows:

1. Internal quality inspection items: mass deviation rate per

unit area, thickness deviation, width deviation, limiting oxygen index,

continued burning time, smoldering time, damage length, electrical strength,

breaking strength, elongation at break, tearing strength, Relative

permittivity, dielectric loss factor, thermal shrinkage;

2. External quality inspection items: the cloth surface is even

and smooth, without obvious creases, broken edges, holes, oil stains, spots,

etc., and the rolls should be neat.