The Importance of Degradation of Sheet Mask Fabric Materials as Fast Moving Consumer Goods Consumables

- Share

- Issue Time

- Nov 1,2022

Summary

At present, there are three scenarios for the degradation test of various materials, namely marine degradation, compost degradation and natural degradation. The most commonly used material testing method is compost degradation.

The Importance of Degradation of Sheet Mask Fabric Materials as Fast Moving Consumer Goods Consumables

At present, there are three scenarios for the degradation test of various materials, namely marine degradation, compost degradation and natural degradation. The most commonly used material testing method is compost degradation.

Most "biodegradable" consumer products are actually very difficult to absorb into the soil through natural degradation. In order to understand the degradation in a specific period, it is necessary to create a set of testing data for the degradation process under specific conditions through the composting process, so as to judge the degradation performance of the material.

In the face of increasingly stringent degradation requirements around the world, in 2019, Proyons Bio-Tech has begun to test the degradability of various mask consumables. In the scope of mask fabric material, we found that compared with other spunlace nonwoven materials, cotton pulp fiber has relatively ideal degradation speed and degradation rate under the same time and test environment.

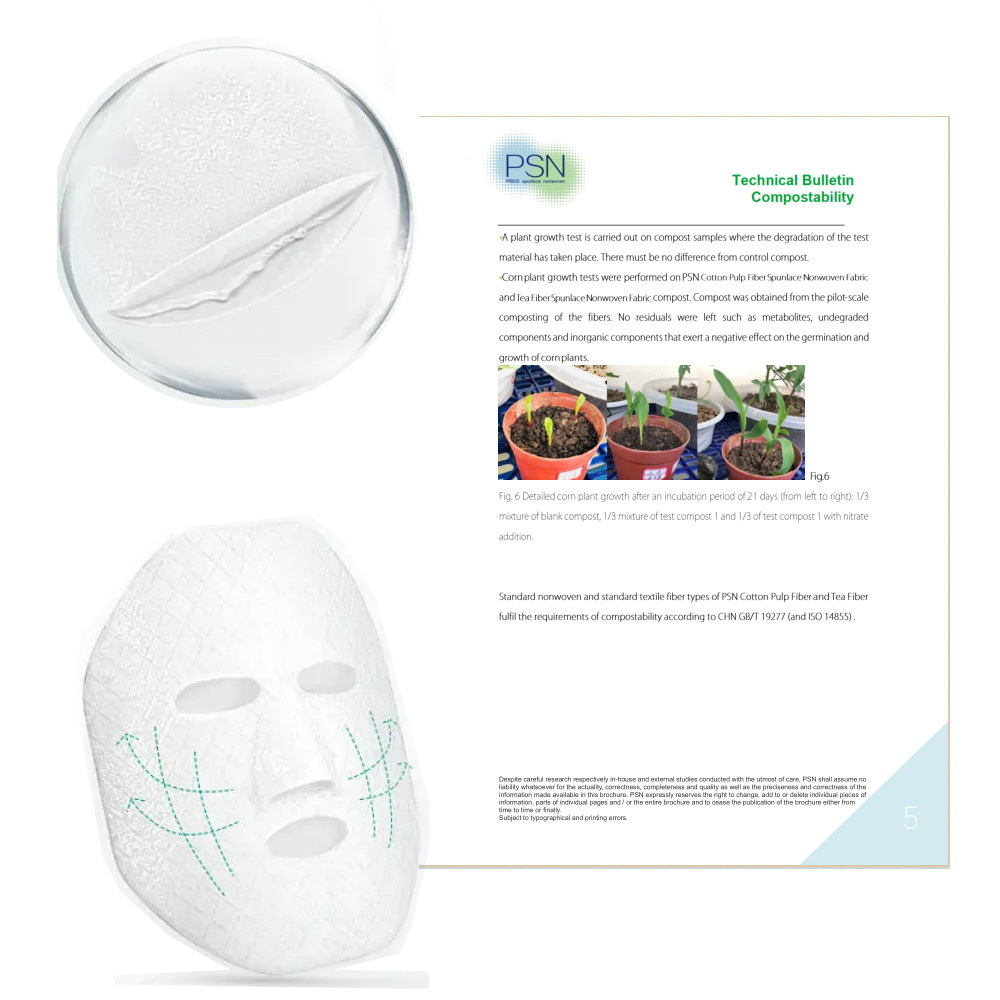

According to CHN GB/T 19277 and ISO 14855 test standards, Proyons Bio-Tech's velvet mask fabric (cotton pulp fiber) and tea fiber mask fabric (wood pulp fiber) have a degradation rate of more than 90% within a 180-day test period . Among them, the velvet cotton pulp fiber has a higher degradation rate of 92% in this period, and the complete degradation time is 201 days. And it can be fully compatible with the soil, become the nutrients in the soil, and be effectively absorbed by the corn seedlings (experimental plants).

Such sheet mask fabric fully meets the degradation requirements of consumer products in different countries and regions. In addition, the cotton pulp fiber mask fabric has up to 14 times water absorption performance, its stickability and transparency are better than Tencel fiber or Tencel spunlace nonwoven fabric, and the hand feel is close to the silk effect.

After the degradable sheet mask fabric is used, it can be rapidly degraded in the natural environment, become fragments used by the environment, and return to nature. Substances produced during the degradation process are beneficial to the environment and circulate in the natural environment. Degradation can be achieved even when entering the marine environment.